Views: 0 Author: Site Editor Publish Time: 2026-01-19 Origin: Site

In modern industrial environments, reliable and safe heat rejection is critical to operational continuity and equipment protection. PED certified dry coolers are engineered to meet stringent European safety requirements while delivering efficient, water-free cooling for demanding industrial applications. Compliance with Pressure Equipment Directive (PED) 2014/68/EU ensures that these systems operate safely under pressure and can be legally placed on the European market.

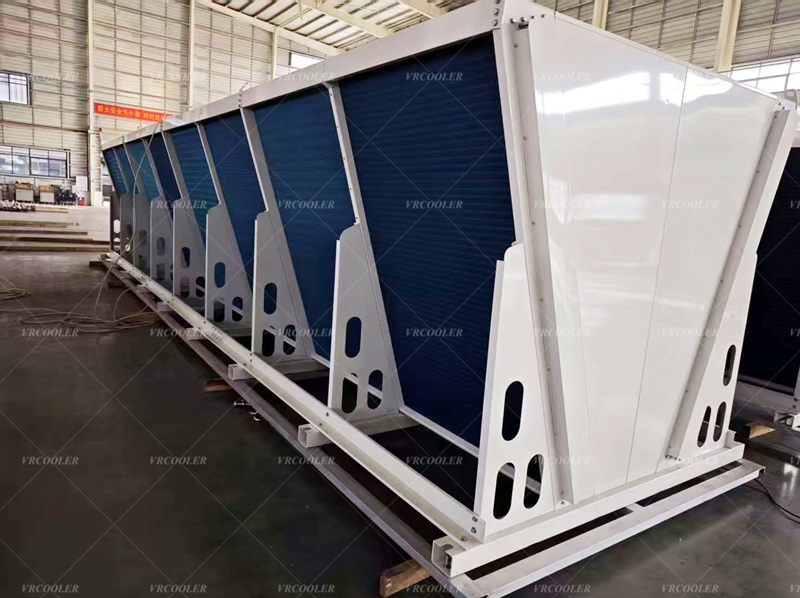

A dry cooler is an air-cooled heat rejection unit that removes heat from process fluids such as water, glycol, or thermal oil without evaporative water consumption. When the internal piping, headers, or coils operate above 0.5 bar maximum allowable pressure, the equipment falls within the scope of PED 2014/68/EU.

A PED certified dry cooler is designed, manufactured, inspected, and documented in accordance with this directive, ensuring structural integrity, pressure safety, and full regulatory compliance.

Industrial processes often involve elevated pressures, temperatures, and continuous operation. Non-compliant pressure equipment can lead to safety risks, downtime, and regulatory penalties. PED certification provides:

Verified pressure integrity and mechanical strength

Compliance with EU legal and safety requirements

Eligibility for CE marking

Reduced project approval and inspection risk

Confidence for end users, EPC contractors, and system integrators

For industrial projects in Europe, PED compliance is frequently a mandatory requirement, not an option.

PED certified dry coolers incorporate robust engineering and quality control measures, including:

Designed according to EN standards and PED safety principles

Suitable for water, glycol, and other industrial heat transfer fluids

Available in copper, stainless steel, carbon steel, or Cu-Ni materials

Welding procedures and welders qualified per applicable standards

Non-destructive testing (NDT) where required

Pressure testing and dimensional verification

Design calculations and drawings

Material certificates and traceability records

Declaration of Conformity and CE marking

PED certified dry coolers are widely used across multiple industrial sectors, including:

Power generation and CHP plants

Gas engine and generator cooling systems

Petrochemical and chemical processing

Compressor and hydraulic oil cooling

Steel, metallurgy, and manufacturing plants

Data centers and critical infrastructure

These systems are especially valuable where water scarcity, contamination risks, or environmental regulations make evaporative cooling impractical.

Choosing a PED certified dry cooler offers several operational and regulatory advantages:

Enhanced safety for high-pressure applications

Water-free cooling, reducing operational and environmental costs

Lower maintenance requirements compared to wet cooling systems

Long service life under continuous industrial operation

Smooth project approval for EU and international installations

PED certified dry coolers can be fully customized to meet specific project demands, including:

Cooling capacity and design ambient conditions

Operating pressure and temperature limits

Fan configuration, noise control, and redundancy

Corrosion protection and special surface coatings

Horizontal or vertical installation layouts

Custom engineering ensures optimal performance while maintaining full compliance with PED requirements.

A PED certified dry cooler for industrial applications provides a reliable, safe, and environmentally responsible solution for heat rejection in high-pressure systems. By meeting the requirements of PED 2014/68/EU, these dry coolers offer not only efficient thermal performance but also the regulatory assurance necessary for successful industrial projects across Europe and beyond.

International Business:+86 0519 8878 2189

Domestic business:+86 0519 8878 2190