Views: 0 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

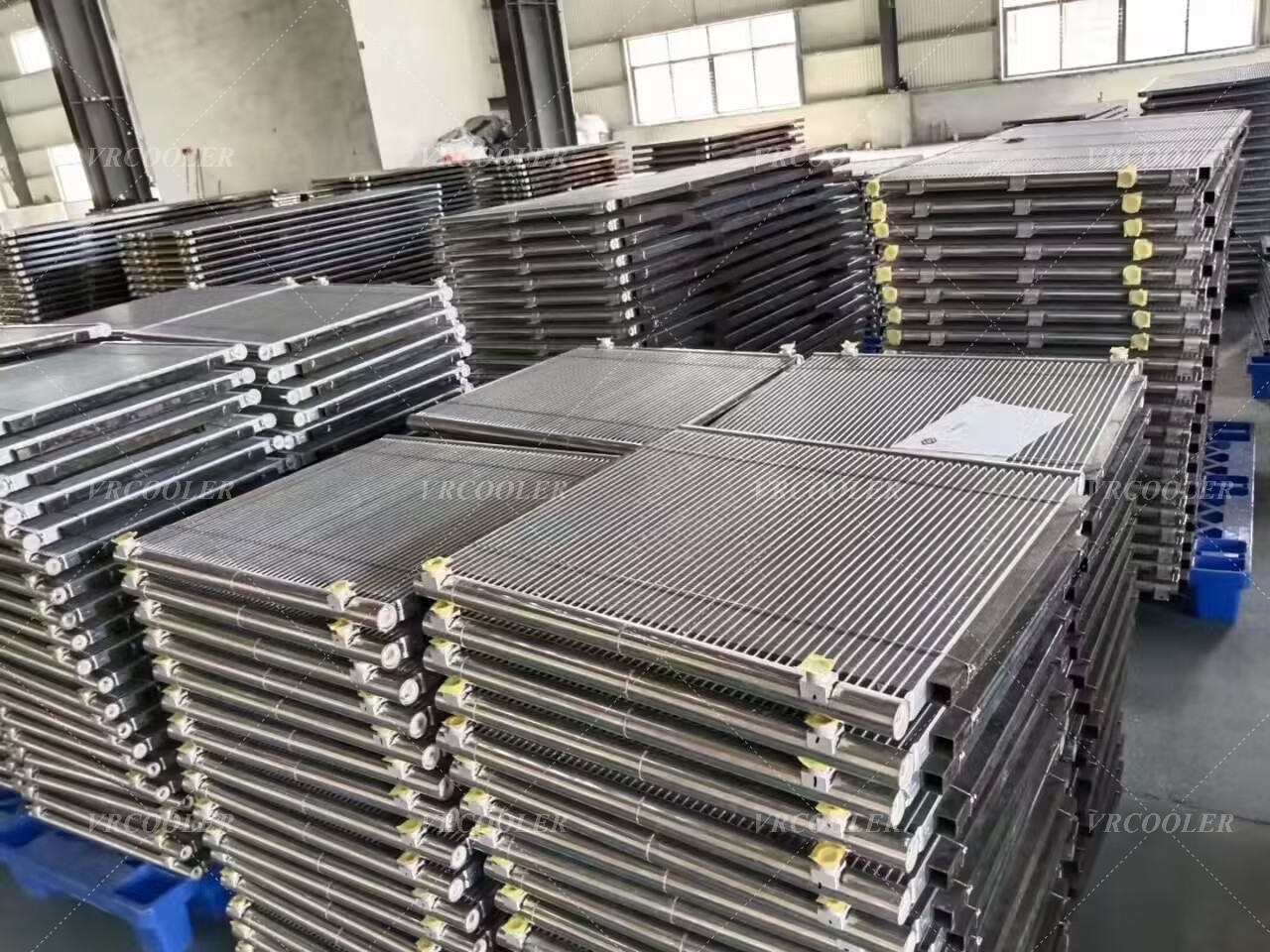

Microchannel condensers have become the preferred heat exchanger technology for modern vehicle air conditioning systems. Compared with traditional tube-and-fin condensers, microchannel designs deliver higher thermal efficiency, lower refrigerant charge, reduced weight, and improved durability—key advantages for passenger cars, commercial vehicles, buses, construction machinery, and electric vehicles (EVs).

Large internal surface area improves condensation performance.

Faster heat rejection even under high ambient temperatures.

Supports compact system design without sacrificing cooling capacity.

Up to 30–50% less refrigerant compared with tube-fin condensers.

Critical for compliance with modern refrigerants such as R134a, R1234yf, and CO₂ (R744).

Lower refrigerant cost and reduced environmental impact.

All-aluminum construction significantly reduces weight.

Ideal for fuel-efficient vehicles and electric vehicles where weight reduction is critical.

Enables tighter packaging in crowded engine compartments.

Brazed aluminum structure minimizes galvanic corrosion.

Optional anti-corrosion coatings (epoxy, hydrophilic, or electrophoretic coatings) extend service life in coastal or high-humidity environments.

Optimized microchannel geometry ensures balanced refrigerant flow.

Enhances compressor efficiency and overall A/C system performance.

Microchannel condensers are widely used in:

Passenger cars and SUVs

Light and heavy commercial vehicles

Buses and coaches

Agricultural and construction machinery

Electric and hybrid vehicles

Off-highway and specialty vehicles

They are suitable for both front-mounted engine cooling modules and remote or roof-mounted A/C systems.

Microchannel condensers are engineered to work with current and next-generation automotive refrigerants:

R134a – legacy systems

R1234yf – low-GWP refrigerant for modern passenger vehicles

R744 (CO₂) – high-pressure systems for EVs and commercial vehicles

Designs can be optimized for high operating pressures, especially for CO₂ systems.

Vacuum brazed aluminum construction

Multi-row or single-row configurations

Custom port geometry for optimal refrigerant distribution

Integrated receiver-drier options

OE-replacement or custom-engineered designs

Microchannel condensers can be tailored to vehicle platform requirements, including mounting points, airflow direction, and connection interfaces.

Lower refrigerant charge supports global emission regulations

Reduced vehicle weight improves fuel economy and driving range

Enhanced efficiency lowers compressor workload and energy consumption

Microchannel condensers represent the most advanced and efficient solution for vehicle air conditioning systems. Their compact size, lightweight construction, superior heat transfer, and compatibility with modern low-GWP refrigerants make them the standard choice for automotive OEMs and aftermarket applications alike. As vehicle efficiency and environmental requirements continue to rise, microchannel condenser technology will remain a core component of next-generation automotive thermal management systems.

How Desiccant Dehumidifiers Improve Paint Drying Time in Spray Booths

High-Performance Gas Sample Heat Exchanger for Gas Analysis Applications

100% Aluminum Air Blast Freezer Evaporator for R-507 Refrigeration Systems

Shell and Tube Heat Exchanger (Reboiler) Used in Carbon Dioxide Removal Systems

How does a boiler exhaust condensing waste heat recovery device work?

Customized Aluminum Tube Heat Exchanger for Commericial Display Cabinet

International Business:+86 0519 8878 2189

Domestic business:+86 0519 8878 2190